| Rigid PCB Capability |

| Layers | ≦36 |

| Materials | Standard FR4/Mid-Tg FR4/Hi-Tg FR4,CEM-1/CEM-3,PTFE,Rogers,Arlon,Taconic,

Teflon,Isola,ITEQ,Dupont,Polyimide,Metal Core Material,Ventec,Nelco |

| Max. PCB Panel Size | 1496mmx620mm |

| Board Thickness | 0.2-12mm |

| Board Thickness Tolerance | ±10% |

| Min Conductor Line Trace/Space | Inner Layers:≧3/3mil(0.075/0.075mm for 1/2oz base Copper) |

| Outer Layers:≧3.5/3.5mil |

For

Via in Pad | Resin plugged hole size | 0.3-0.75mm |

| Resin plugged board thickness | 0.3-8mm |

| Resin plugged maximum aspect ratio | 20:1 |

| Resin plugged minimum hole to hole space(mm) | 0.65mm |

| For HDI | Min. mechanical drilling hole diameter | 0.15mm |

| Min. laser drilling hole diameter | 0.075mm |

| Max. aspect(micro-via) | 1:1 |

| Max. dielectric thickness for laser drill | 0.05-0.15mm |

| Bottom pad size(under micro-via) | Hole Size+0.17mm |

| Top side pad size(on micro-via) | Hole Size+0.15mm |

| Copper filling | Y |

| Via in pad design | Y |

| Buried hole resin plugged | Y |

| Min. via size can be copper filled | 0.075mm |

| Min plated hole size | 20um(0.8mil) |

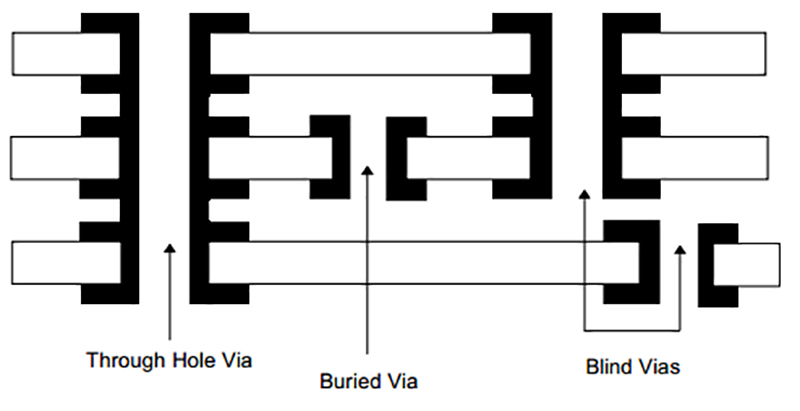

| Min Blind/Buried hole size | 0.2mm(8mil) |

| Min Annular Ring | ±0.076mm(±3mil) |

| Min width of cutout (NPTH) | 0.8mm |

| Min width of slot hole (PTH) | 0.6mm |

| Solder mask color | green, red, blue, white, yellow, purple, black, orange, LPI, matt green |

| Silkscreen color | White, Yellow, Red, Black |

| Surface finish | ENIG, Immersion Tin, HASL, HASL-LF, OSP, Gold finger, Immersion Silver |

| Outline | Routing, V-cut, Bridge, Stamp hole |

| Outline Tolerance | ±0.15mm (±6mil) |

| Hole Tolerance | PTH +/-3mil |

| NPTH +/-2mil |

| Controled Impendence | +/-5%(<50Ω), +/-10%(≧50Ω) |

| E-Test | Flying probe test:0.4-6.0mm, max 19.6"*23.5" |

| Min spacing from test pad to board edge:0.5mm |

| Min conductive resistance:5Ω |

| Max insulation resistance:250mΩ |

| Max test voltage:500V |

| Min test pad diameter:6mil |

| Min test pad to pad spacing:10mil |

| Max test pad to pad spacing:10mil |

| Max test current:200MA |

| AOI | Orbotech SK-75 AOI:0.05-6.0mm, max23.5"*23.5" |

| Orbotech Ves machine:0.05-6.0mm, max23.5"*23.5" |