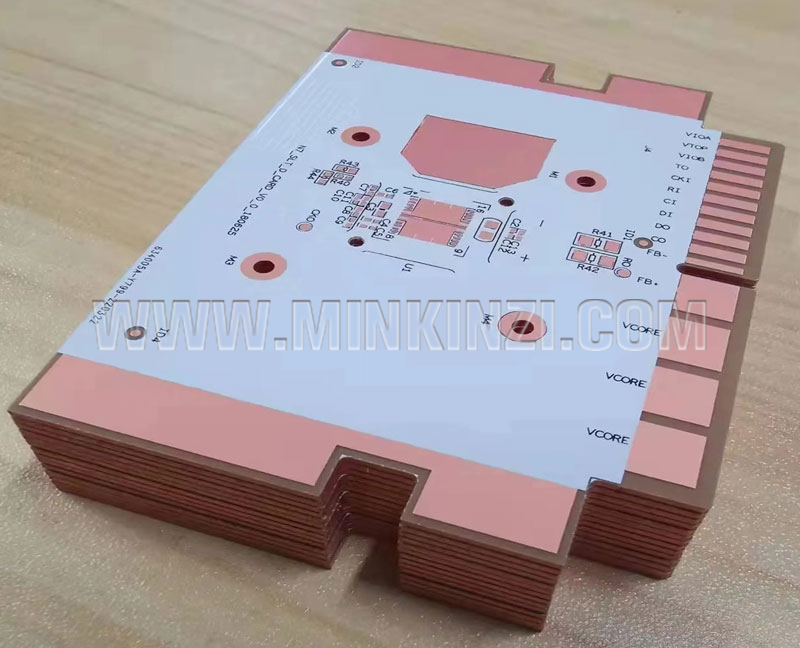

Copper substrate circuit board is generally used in electronic products, LED lighting, solar cells, automotive electronics, medical equipment and other products.

First, the field of electronic products

In the field of electronic products, copper substrate is widely used in mobile phones, tablet computers, digital cameras, audio equipment and so on. The circuit boards in these devices require stable, reliable support, and copper substrates are the preferred materials in the manufacture of electronic products due to their advantages of high strength, high corrosion resistance, high thermal conductivity and high reliability.

Second, LED lighting field

Copper substrate is also widely used in the field of LED lighting. LED lighting equipment needs efficient heat dissipation function to ensure long-term stable work. Due to its high thermal conductivity, the copper substrate can effectively improve the cooling effect of the LED lamp, so as to ensure the life and light efficiency of the LED lamp.

Third, the field of solar cells

Copper substrate is also used extensively in solar panels, which can not only improve the conversion efficiency of solar cells, but also carry the transmission and processing of the internal circuit of solar panels.

4. Automotive electronics

Automotive electronics refers to the integration of various electronic devices in the car, and copper substrate has also been widely used in this field. Copper substrate with its high strength, high thermal conductivity, high reliability and other characteristics, has become a solid foundation in the manufacturing of automotive electronic products. For example, in-car computers, central control systems, etc.

5. Medical device field

Second, the application of copper substrate in electronic products

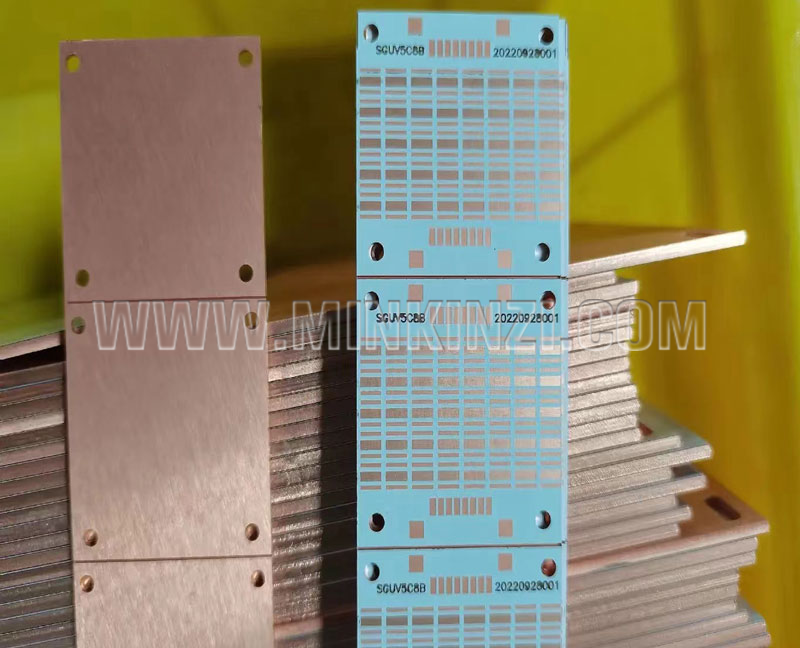

1, semiconductor devices: Copper substrate is a commonly used heat dissipation material, which is widely used in the heat dissipation link of semiconductor devices. It has good electrical conductivity, can provide stable current and voltage, and can effectively conduct the heat generated by the device to ensure long-term stable operation of the device.

2, LED package: LED (Light Emitting Diode) is a light source with environmental protection, energy saving, long life, high reliability. The copper substrate is directly connected with the LED chip, which can realize the unobstructed high-strength circuit, which is conducive to improving the brightness and stability of the LED.

3, high frequency circuit: Copper substrate can be used as a signal transmission medium in high frequency circuit, with low loss, low noise, high frequency response and other advantages. This kind of application widely exists in the field of radio equipment, radar system, communication system and so on.

4, solar cells: copper substrate can be used as a battery plate, widely used in solar cells. Copper substrate has good electrical conductivity and is used as the basic material for the integration of solar cell modules, which converts light energy into electricity through solar irradiation.

Copper substrates also play an important role in the field of medical devices. Medical devices need high-precision and high-reliability circuit boards as support, and the material selection of copper substrates is strictly required. The advantages of copper substrate are its high reliability, stability, strong oxygen resistance and other characteristics, which can meet the requirements of the medical device field.